Ompa ProductsSupport Service

The multi-year experience and the vast competence gained by OMPA personnel represent some of the Company’s key strengths which are daily offered to our valued Customers.

Support Services offered by OMPA include:

Support ServicesEngineering Design

OMPA is able to provide engineering support to solve Customer technical issues or to help them in product optimization or product development.

Our Design and Technical Department uses 2D-3D softwares, such as Autocad and Solid Edge, and are constantly supporting our Clients as well as our internal manufacturing activities.

Full Engineering Design and Testing, which may involve external body certifications (i.e.PED, CE Mark, etc.) are also provided upon request.

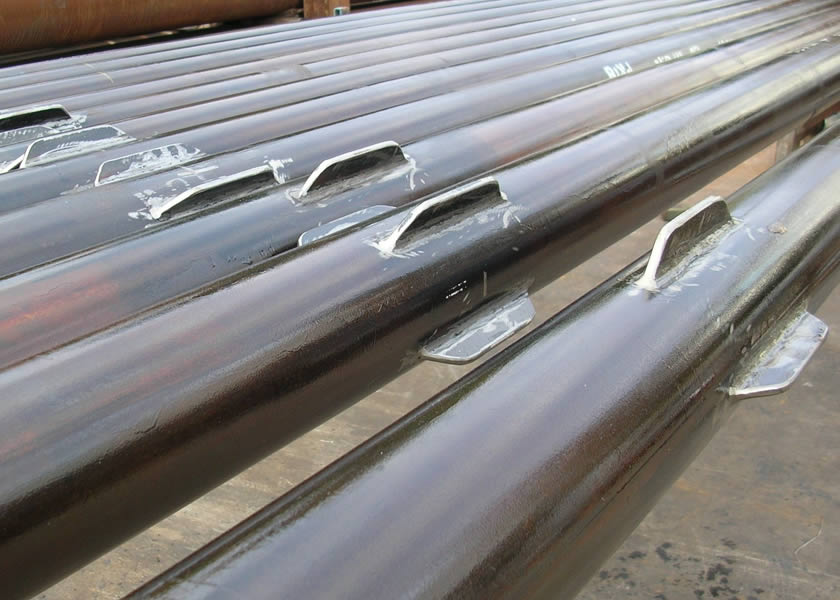

Support ServicesField Inspection

Inspection Service (Visual and NDT) is provided to customers when in adherence to our core activities.

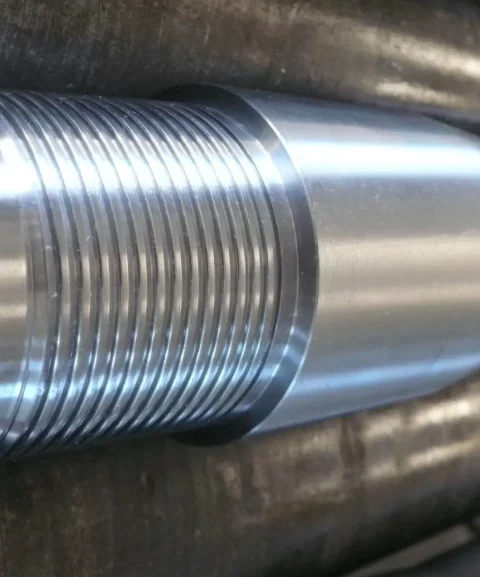

Threaded connections verification is performed by using full instrument package, dedicated gauges and specific NDT equipment.

Inspections are routinely performed in house, but can also be extended to the field-site to guarantee full assistance and support to OMPA valued Customers.

Support ServicesMaintenance

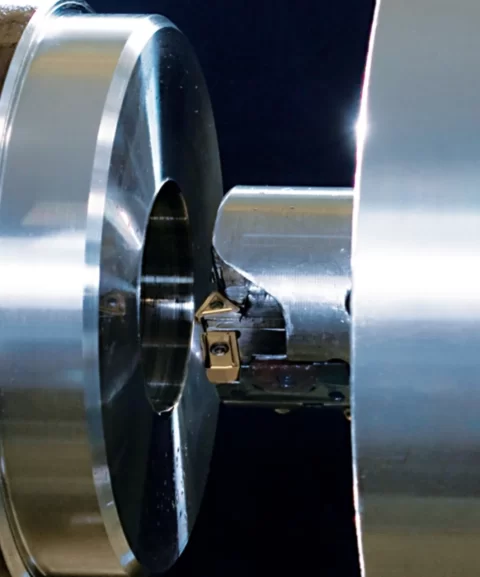

Customer equipment refurbishment is routinely performed in-house with all activities and inspections duly documented and certified.

Onshore / Offshore maintenance is also performed on specific instances to fully support OMPA Customers.

Support ServicesThermal Arc Spray

Thermal arc spray coating is a highly cost-effective and a straight-forward method for adding superior properties and performance qualities to a given engineering surface.

Thermal Arc Spraying is widely used to create High Performance Parts from low cost substrates, to increase Service Life by spraying high hardness on softer substrates.

Thermal Arc Spray technique is a coating process in which melted materials are sprayed onto a surface which is not subject to a significant overheating.

The coatings are usually metallic, or a combination of these materials, to meet a range of physical criteria and include aluminum, copper, zinc, nickel chrome, brass, molybdenum, titanium, low/high carbon steel, stainless steel, tungsten carbide, etc. Coating thickness ranges between few microns and several millimeters.

Typical applications

- Conductivity Alteration

- Corrosion protection

- Dimension restoration

- Fouling protection

- Hardfacing

- Special Coating

- Surfaces Reclamation

- Thermal Barrier Coating

- Wear / Sliding control